Bound4blue Integrates Siemens Technology into the eSAIL® System. Boun4blue innovative technology is a suction sail that harnesses the power of the wind to propel ships and reduce their dependence on fossil fuels.

The reduction of fuel consumption and sustainability have been the major challenges in maritime transport for years. With Siemens digitalization technology, maximizing fuel savings and, consequently, reducing ship emissions are achieved.

The role of Siemens has been crucial in ensuring that the ship’s control system is robust, autonomous, and requires minimal intervention from the ship’s crew.

“Thanks to the technology of our Sinamics equipment, we can synchronize the movement of large variable loads with the precision and dynamics that bound4blue needs to support its clients in their sustainability strategy,” says Alfonso Sánchez Quintela, Siemens Account Manager.

To provide direct propulsion to the vessel, the sail requires minimal energy for its operation. Sinamics technology and energy meters in ET200SP format provide data on the sail’s electrical consumption.

“The control system of our sails touches on various branches of industrial automation and requires compliance with six fundamental features,” says Marçal García Tobella, Head of Automation and Control at bound4blue.

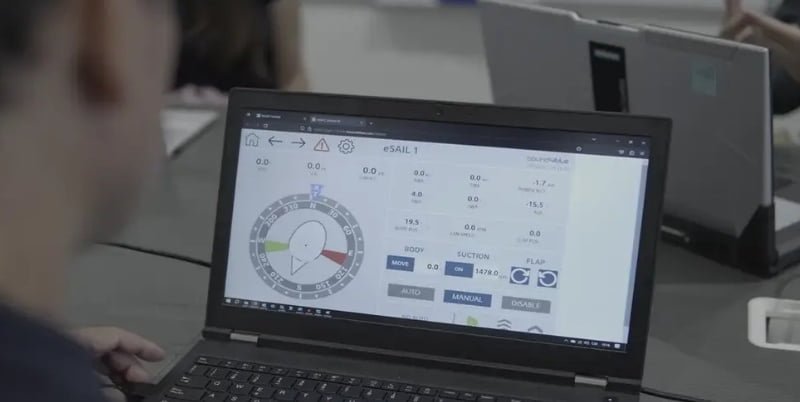

“These features include robustness for aggressive environmental conditions, precise and synchronized position control, telecommunications in different protocols, programming of aerodynamic algorithms, user-friendly and intuitive graphical visualization, and lastly, cybersecurity protection.”

Siemens meets all these requirements by offering certified equipment for the maritime environment. The project combines the technology of the S7-1500 PLC, Sinamics frequency converters, and WinCC Unified touch panels to achieve smooth and precise rotation of the sail body and flap and to communicate with various components using specific naval protocols.

At the same time, a demanding code is implemented in terms of aerodynamic control algorithms. An attractive user interface has also been integrated, facilitating navigation for the captain in a clear and intuitive way.

In terms of cybersecurity, Siemens technology in this project allows for the protection of equipment programs and encryption of communications. All of this is integrated into a system and employs the TIA Portal software to group the configuration and programming of all the equipment involved.

These digital tools also allow us to analyze data provided by weather stations. With this information, the best strategy for providing thrust to the ship in real-time is established, regardless of the route taken. This maximizes fuel savings and reduces emissions from ships.

Source Bound4blue