Swiss marine power company WinGD has successfully completed shop tests of its groundbreaking variable compression ratio (VCR) technology, confirming that X-DF engines equipped with VCR can significantly reduce methane emissions, offering shipowners a more sustainable and cost-efficient solution for their fleets.

Table of Contents

VCR Technology Achieves Groundbreaking Results

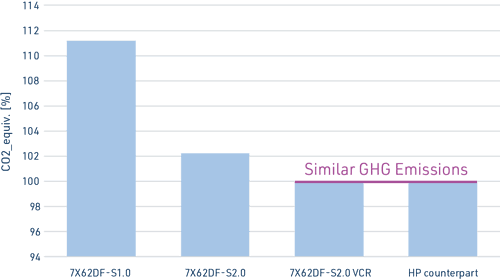

The tests, carried out at the Mitsui E&S DU (MESDU) facilities in Japan, focused on the first X-DF2.0 engines with VCR, which are being built for bulk carriers owned by NYK Lines. During the tests, the six-cylinder, 62-bore engine demonstrated a reduction of approximately 30% in methane emissions, compared to the same engine without VCR. This means methane slip was reduced to just 0.83% of gas consumption, well below the default methane slip levels specified by both EU regulations and IMO for low-pressure, low-speed dual-fuel engines. This reduction is expected to be even more significant for engines with a larger bore.

Efficiency Gains Across Fuel Modes

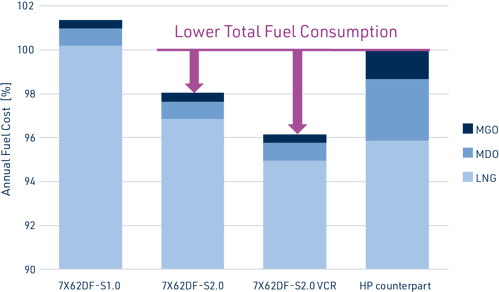

In addition to the reduction in methane emissions, the VCR technology also resulted in fuel consumption reductions, with up to 5.8% improvement in gas mode and up to 6.9% in diesel mode. These improvements translate to lower fuel costs and reduced CO2 emissions, providing significant operational advantages over previous engine technologies. These results were measured using a typical car carrier operating profile, providing valuable insight into the real-world impact of VCR-equipped X-DF engines.

Peter Krähenbühl, Vice President Product Centre at WinGD, commented on the successful results:

“Over the past decade we’ve worked to ensure that the unmatched reliability and low capital expenditure of X-DF engines are supported by the lowest possible overall GHG emissions. The fuel consumption and methane slip reductions achieved by VCR bring us to that point. Low GHG emissions will be fundamental for shipowners as carbon pricing measures take effect, which is why we have already seen strong uptake, with well over 100 new X-DF engines ordered with VCR so far.”

A Technological Leap for Decarbonization

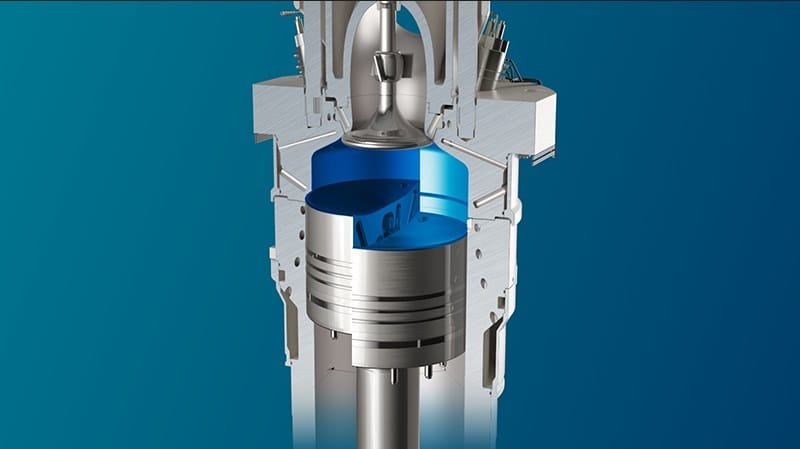

The VCR technology is designed to automatically adjust the engine’s compression ratio to optimize combustion, taking into account factors like engine load, fuel type, and ambient conditions. This dynamic approach ensures that X-DF engines achieve maximum efficiency while maintaining low methane slip levels, directly contributing to GHG emission reductions.

The VCR solution is compatible with all new X-DF engines and has already been successfully implemented in a retrofit package, yielding promising early results. WinGD’s commitment to lowering GHG emissions is evident in the uptake of the new technology, with over 100 new X-DF engines ordered with VCR already.

Addressing Methane Slip in Regulatory Landscape

As regulations on methane slip evolve, both European and IMO standards will incorporate mechanisms for updating default methane slip factors. This means shipping companies can now submit actual methane slip measurements, which will allow them to lower their carbon costs based on any reductions in methane slip. WinGD is actively contributing to this regulatory process through various industry associations, ensuring that its technology aligns with the latest carbon pricing mechanisms.

Future of LNG as a Marine Fuel

WinGD envisions LNG as a marine fuel, with the long-term goal of replacing fossil LNG with zero- or near-zero emissions alternatives, such as biomethane and synthetic LNG. By reducing methane emissions, WinGD’s X-DF engines will help lower the overall GHG impact regardless of the LNG’s source. WinGD is also developing ammonia and methanol-fueled engines, providing ship operators with a variety of fuel options to support their decarbonization strategies.

This milestone represents a major advancement in WinGD’s efforts to provide cleaner, more efficient maritime power solutions. The X-DF technology with VCR continues to push the boundaries of sustainable shipping, offering both economic and environmental benefits to shipowners as they navigate the future of the maritime industry.

About WinGD

WinGD (Winterthur Gas & Diesel) is a global leader in marine power solutions, advancing the decarbonisation of marine transportation through sustainable energy systems. The company offers cutting-edge technologies in emissions reduction, fuel efficiency, hybridisation, and digital optimisation. WinGD’s two-stroke low-speed engines set the industry standard for reliability, safety, and environmental design. Based in Winterthur, Switzerland, WinGD has been at the forefront of marine engine technology since its inception in 1893 and continues to lead the way in transforming the maritime industry towards a more sustainable future. WinGD is a member of the CSSC Group.

Source Winterthur Gas & Diesel