We are excited to share an enlightening article from Veritas Petroleum Services (VPS), a renowned name in the maritime sector, delving into the intricate world of marine fuels, this article addresses critical aspects of fuel quality, stability, and the challenges arising from chemical contamination within Very Low Sulphur Fuels (VLSFOs). With insights shared by VPS’s Group Commercial Director, Steve Bee.

As the shipping industry rightfully focuses on reducing its carbon footprint and endeavors to comply with a plethora of decarbonization legislation, it might be easy to overlook the fact that traditional fossil fuels remain the primary energy source for the majority of the global fleet. Therefore, the management and quality of fossil fuels continue to play a crucial role in safeguarding vessels, their crews, and the environment.

Being the most widely utilized fossil fuel, Very Low Sulphur Fuels (VLSFOs) require heightened attention in terms of fuel management. Currently, VLSFOs constitute 55% of all marine fuel samples received by VPS for quality testing. Despite the absence of official standard specifications for VLSFOs within ISO8217, most VLSFOs are assessed against RMG380 specifications, recognizing that VLSFO viscosities are significantly lower than 380cSt. Presently, 68% of tested VLSFOs exhibit viscosities ranging between 20cSt and 180cSt. This disparity can profoundly affect fuel transfer and injection temperatures on vessels, necessitating less heating to achieve the optimal injection viscosity. It would be advantageous to introduce both a minimum viscosity specification limit and a current maximum viscosity limit within ISO8217 for VLSFOs.

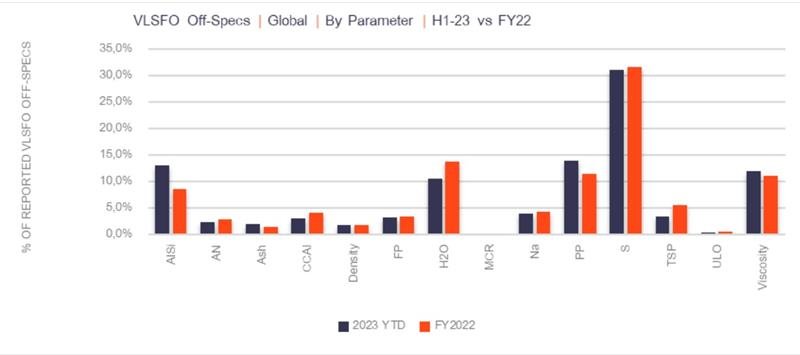

Currently, 3.8% of tested VLSFOs display at least one off-specification parameter. This is a favorable comparison against the off-specification rates of 11.4% for HSFO fuels and 16.9% for MGO fuels. However, VLSFO off-specifications potentially raise greater concerns than some associated with HSFO and MGO. Parameters such as sulfur content, water presence, cold-flow properties, and cat-fines are the most common culprits for VLSFO off-specifications.

Sulfur off-specification stands as the most prevalent among all VLSFO off-specifications, contributing to over 30% of all instances. However, recent test results demonstrate an improvement in sulfur off-specification compared to the state in 2021. Presently, only 1.6% of tested VLSFOs exceed the 0.50% sulfur limit, as opposed to 2.4% in 2021.

Moreover, data indicates that fuel suppliers in the current year are generating more fuel falling within the 0.41%-0.46% sulfur range than in the 0.47%-0.50% range observed in the past two years. This trend translates to a reduced likelihood of VLSFOs falling outside the 95%-confidence interval or deviating from specifications.

Due to the higher paraffinic content in VLSFOs compared to HSFO fuels, wax precipitation when exposed to colder temperatures is more likely.

The formation of wax crystals during storage and usage presents a potential source of significant operational issues with VLSFOs. Therefore, testing for both wax appearance temperature (WAT) and wax disappearance temperature (WDT) is crucial, as the fuel’s pour point is an unreliable indicator of potential cold-flow problems.

In 2019, VPS developed an exclusive test to measure WAT and WDT in VLSFOs, a tool many customers now rely on to safeguard their vessels against wax precipitation and its potentially harmful consequences.

Present global averages indicate a VLSFO pour point of 16°C, with an average WAT of 38°C and average WDT of 48°C. These figures underscore the inadequacy of using +10°C above the pour point as a gauge for cold-flow properties in VLSFO blends, rendering it insufficient and an inappropriate risk mitigation measure.

In instances of elevated WAT and WDT results, vessels should contemplate increasing temperatures in onboard separators, storage facilities, settling, and service tanks. Nonetheless, VLSFOs with a short shelf life and high WAT might not be suitable for storage, as heating such fuel accelerates aging and heightens the likelihood of fuel sludging.

VLSFOs with low viscosity but high WAT & WDT need to be heated to ensure a stable flow and prevent wax formation. These fuels will probably require cooling before entering the main engine due to their low viscosity. However, this could lead to operational challenges, including wax formation if the fuel temperature falls below the WAT.

Stability issues concerning VLSFOs have been a concern since their introduction in 2019. Even today, we continue to observe spikes in Total Sediment Potential (TSP) globally.

Some VLSFO blends may appear stable during bunkering but exhibit instability over time, often within a week or two. The process of heating the fuel in tanks (for proper storage and transfer) and purifiers (to achieve effective purification) can compromise the fuel’s stability and accelerate the aging process.

VLSFOs that are incompatible can lead to separator sludging and filter clogs, resulting in numerous vessels encountering compatibility issues when transitioning between MGO and VLSFO or vice versa.

VLSFOs characterized by high WAT/WDT and elevated cat-fine levels necessitate operating separators at higher temperatures and more frequent discharge intervals. Unfortunately, this approach can trigger wax formation, impacting both purifier operation and the filtration system of the fuel.

Lastly, concerning stability, VLSFOs with elevated WAT/WDT, coupled with chemical contamination and low viscosity, are unlikely to be manageable onboard vessels. In such scenarios, the only solution is to de-bunker the fuel.

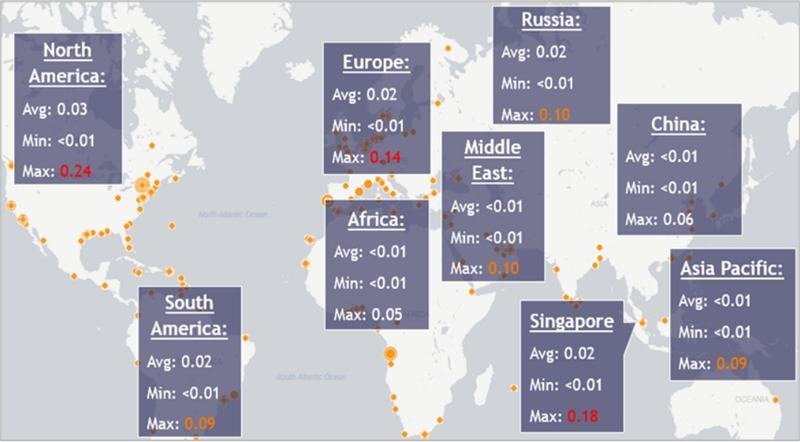

Between February and July 2023, VPS identified contamination in VLSFO fuels in Houston. This contamination revealed the presence of two specific isomers of Dicyclopentadiene (DCPD) at concentrations ranging from 1,000ppm to 40,000ppm. These particular isomers were:

- Di-hydro dicyclopentadiene – Chemical CAS Number: 4488-57-7

- Tetra-hydro dicyclopentadiene – Chemical CAS Number: 6004-38-2

DCPDs are unsaturated chemical compounds that can polymerize and oxidize under specific conditions. Polymerization of DCPDs results in the fuel becoming sticky and more viscous, impeding the movement of components such as fuel pump plungers and fuel injector spindles. These effects can lead to damage in the fuel injection system, potentially causing excessive sludge formation over time.

In this particular instance, 12 vessels that had bunkered fuel in Houston experienced severe operational issues and damages to auxiliary engines and fuel delivery systems. These issues were caused by fuel supplied by four different suppliers. The problems observed included fuel leakage in the Injection Control Unit (ICU) units and fuel pumps failing to generate the required fuel pressure.

To address the risks associated with chemical contamination of VLSFOs, VPS recommends integrating their GCMS-HS Chemical Screening service with each VLSFO bunkering. This service, a pre-burn, rapid, and cost-effective test, identifies volatile chemicals within VLSFOs like styrene, DCPD, and chlorinated hydrocarbons, offering heightened vessel protection.

In conclusion, VLSFOs, as the predominant marine fuel powering today’s global fleet, have the potential to trigger various operational and compliance challenges due to their diverse quality. To mitigate potential risks stemming from poor cold-flow parameters, fuel stability, chemical contamination, low viscosity, and sulfur non-compliance, effective fuel management and testing can significantly aid in reducing or even eliminating such risks.

Source VPS Veritas Petroleum Services