Rotterdam – Antwerp | January 05, 2026 – The landscape of ARA Region bunkering has officially shifted. As of January 1, 2026, the Port of Rotterdam and the Port of Antwerp-Bruges have enforced a landmark mandate: all bunker vessels operating within these jurisdictions must utilize a certified Mass Flow Meter (MFM) for the delivery of residual distillates and biofuels.

This joint initiative aims to eliminate structural quantity discrepancies and position the ARA region as a global leader in maritime transparency.

Table of Contents

The End of “Paper” Bunkering

For decades, the industry relied heavily on manual tank soundings, a process prone to human error and “cappuccino effect” inaccuracies. By transitioning to MFMs, the ports have introduced a tamper-resistant, auditable system that measures the mass of the fuel directly, rather than its volume. This distinction is critical, as mass remains constant regardless of temperature or pressure fluctuations.

Key Requirements (Effective Jan 1, 2026):

- Mandatory Equipment: All bunker barges must be equipped with MFM systems certified to ISO 22192 standards.

- Fuel Scope: The mandate specifically covers residual distillates and biofuels.

- Licensing: Operators must hold a valid bunkering license, and all MFM systems must be registered with the respective Harbour Masters.

The Evolving Role of the Bunker Surveyor

Contrary to some industry speculation, the mandate does not make the bunker surveyor obsolete; rather, their role has transitioned from manual measurement to system auditing. Port authorities emphasize that surveyors remain vital for:

- System Integrity: Verifying MFM seals and calibration certificates before transfer.

- Quality Control: Overseeing mandatory sampling procedures.

- Independent Witnessing: Ensuring the strict MFM protocol is followed from start to finish.

Enforcement and Compliance

The Port of Rotterdam and Port of Antwerp-Bruges have made it clear that compliance is non-negotiable. The Harbour Master’s Divisions are now conducting unannounced inspections and audits. Vessels found operating without a certified MFM or failing to adhere to the new protocols risk heavy fines or the immediate revocation of their bunkering license.

Why It Matters for the Industry

This shift is a direct response to years of industry pressure to “level the playing field.” For shipowners, it provides certainty that they are receiving exactly what they pay for. For reputable suppliers, it removes the competitive disadvantage created by “creative” measurement practices. Furthermore, with the requirements of FuelEU Maritime, precise measurement is now a prerequisite for accurate emissions reporting.

Bunker Incident From

The Port of Rotterdam has updated its “Bunker Incident Form” and published new placards for enforcement officers. Stakeholders are encouraged to visit the official port portals for the latest technical FAQs.

Operational Protocol (Code of Practice)

Beyond the hardware requirement, the Port of Rotterdam have released Code of Practice that redefines the roles of the Barge Representative, Chief Engineer, and Bunker Surveyor. To ensure the integrity of the MFM system, the port authorities have outlined three-phase workflow for every delivery:

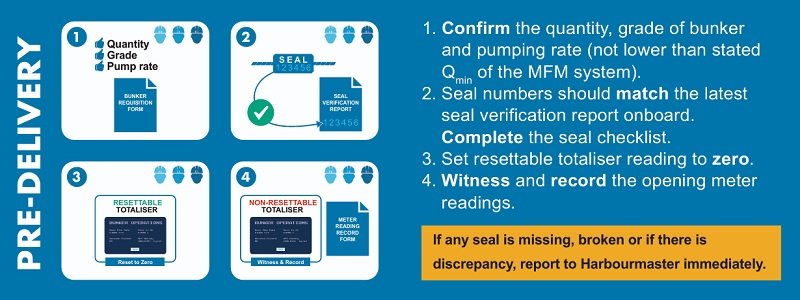

1. Pre-Delivery: The Verification Phase

Before fuel begins to flow, the following “Zero-Verification” steps must be completed:

- Documentation & Grade: Parties must confirm the bunker quantity, grade, and agreed pumping rate. The rate cannot be lower than the Qmin stated on the MFM system.

- Seal Integrity: Physical seals must match the latest Seal Verification Report. If any seal is broken, the Harbourmaster must be notified immediately.

- Totalizer Reset: The resettable totalizer must be set to zero in the presence of all parties.

2. During Delivery: Monitoring Flow

- Line Filling: Cargo lines must be filled as fast as practicable at the start to ensure meter accuracy.

- Stoppage Logging: Any interruption must be documented. The MFM system will monitor for aeration, and the “Aeration Present” indicator must be checked on the display.

- Stripping: Tank stripping and line clearing are strictly confined to the end of the operation.

3. Post-Delivery: Finalizing the Transaction

- Closing Readings: All parties must witness and record the closing meter readings.

- Post-Check: A final verification ensures seals remain intact.

- No Re-pumping: Once the bunker metering ticket is printed, no re-pumping of bunkers is allowed.

Dispute Management Framework: Quantity & Quality

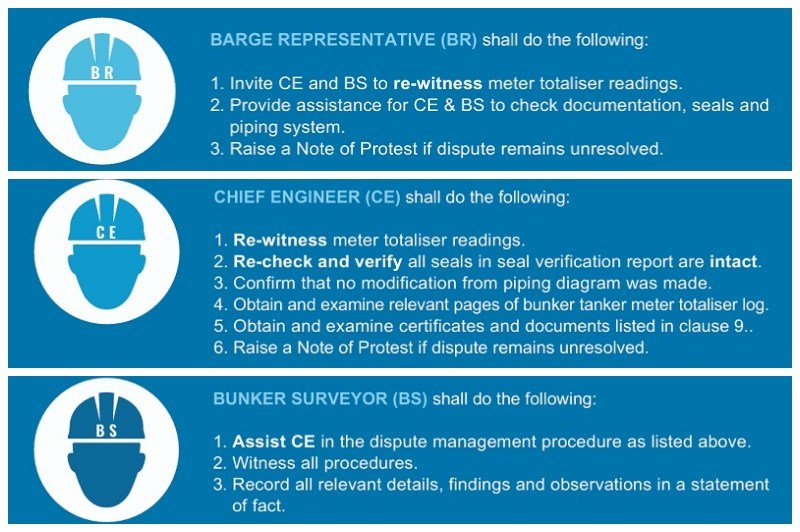

The Code of Practice introduces a formalized Dispute Management Framework to replace informal deck-side negotiations with a transparent, auditable process.

Quantity Disputes

If a discrepancy arises, the protocol requires immediate action

- The Barge Representative (BR): Must invite the Chief Engineer and Bunker Surveyor to re-witness meter totalizer readings and assist in a full inspection of the documentation, physical seals, and piping systems. If the dispute remains unresolved after these checks, the BR is required to raise a formal Note of Protest (NoP).

- The Chief Engineer (CE): Must re-verify the meter readings and ensure all seals listed in the Seal Verification Report remain intact. The CE is also responsible for examining the bunker tanker’s meter log and confirming that no unauthorized modifications were made to the piping diagram. An NoP must be raised if the discrepancy persists.

- The Bunker Surveyor (BS): Acts as the independent lead witness. The BS must oversee all dispute procedures and record every detail, finding, and observation in a comprehensive Statement of Fact.

All unresolved quantity disputes must be reported to the Port Authority. A copy of the report or complaint must be lodged with the Harbourmaster of Rotterdam or Antwerp-Bruges via the official bunkering email addresses within 24 hours.

Quality Disputes

While the MFM system ensures quantity precision, fuel quality remains a separate pillar of maritime transparency. Any quality-related claims (off-spec fuel) must be reported to the Port Authorities through the same dedicated bunkering portals.

- Reporting Window: Quality disputes must be formally lodged within 14 days of the delivery.

Official Oversight & Strategic Alignment

The ILT Bunkering Procedure: In the Netherlands, the Human Environment and Transport Inspectorate (ILT) governs compliance. All operators must follow legally mandated sampling to ensure fuel matches the Bunker Delivery Note (BDN). The ILT actively monitors bunkering operations to ensure safety and environmental compliance. Full ILT details here.

Alignment with Singapore: This mandate brings the ARA region into alignment with the Port of Singapore. Notably, MFM systems certified in Singapore are recognized in Rotterdam and Antwerp-Bruges, ensuring global interoperability for international shipowners.

Bunker Crew & Chief Engineer Quick-Action Checklist

| Phase | Action Item | Responsibility |

| Pre-Delivery | Verify Qmin (Minimum Flow Rate) of the MFM system. | BR / CE |

| Pre-Delivery | Check physical seals against the Seal Verification Report. | BR / CE / BS |

| Pre-Delivery | Set resettable totalizer to 0.0000. | BR / CE |

| Delivery | Fill cargo lines at max practicable speed to stabilize the meter. | BR |

| Delivery | Monitor for “Aeration Present” on the display. | CE / BS |

| Post-Delivery | Witness closing meter readings and record “Mass in Air.” | All Parties |

| Post-Delivery | Re-verify that all MFM seals remain intact. | CE / BS |

Disclaimer: All information in this article is current as of January 5, 2026. Bunkering regulations and port protocols are subject to change by authorities without prior notice. The information in this article is solely for knowledge sharing and awareness. Readers and industry stakeholders are advised to perform their own due diligence and consult the official Port of Rotterdam or Antwerp-Bruges circulars for more information.

Source: The Port of Rotterdam | Port of Antwerp-Bruges | ILT