Shipshave – In a significant step toward advancing sustainability in the maritime industry, Hapag-Lloyd, one of the world’s leading container shipping companies, has successfully implemented Shipshave’s In Transit Cleaning of Hull (ITCH) solution. This initiative has enabled the company to significantly reduce emissions and cut operational costs. The results of this green technology were thoroughly analyzed and verified by class society DNV, underscoring the effectiveness of proactive fouling removal in improving fuel efficiency and reducing environmental impact.

Hapag-Lloyd collaborated with Shipshave and DNV to conduct a comprehensive study on two container ships, one with a capacity of 8,749 TEU and the other 18,800 TEU. These vessels, differing in age and trading profiles, were equipped with the ITCH system, which uses a semi-autonomous robot to clean hulls while the vessels are in transit. The analysis spanned 17 months, allowing for an in-depth assessment of the long-term performance trends of the ships.

The results confirmed the impressive benefits of proactive hull cleaning. The vessels showed marked improvements in fuel efficiency and emissions reductions. One of the ships experienced a remarkable 16% performance improvement, equivalent to a reduction of approximately 8.4 tons of fuel per day. This is the same as eliminating the emissions of over 4,900 fossil-fuel-powered cars during the same period. The second ship, which initially showed better performance, still saw a significant 5% reduction in fuel consumption, demonstrating the positive impact of regular hull cleaning.

Nikhilesh Bhatia, Director of Fleet Energy Efficiency at Hapag-Lloyd, expressed his satisfaction with the findings. “We are very pleased that this analysis from DNV confirms our internal assessment of the result achieved by the implementation of ITCH. This method reflects our proactive approach to reducing emissions caused by biofouling,” said Bhatia. He added that the use of ITCH has enabled Hapag-Lloyd to maintain its leadership in sustainability by reducing drag and lowering emissions over the long term.

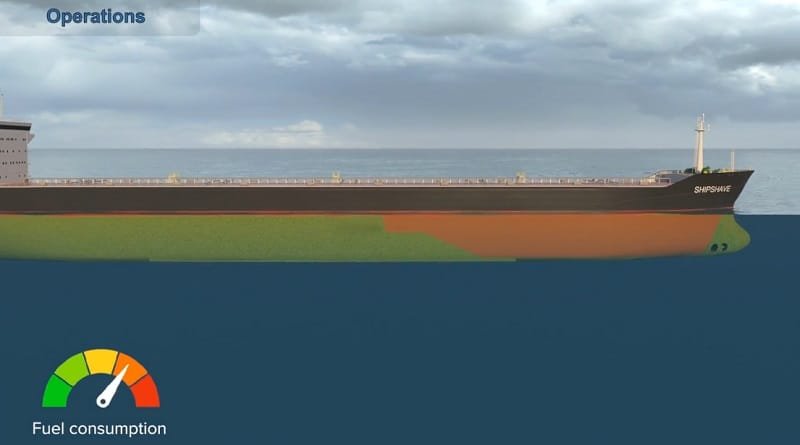

The ITCH system works by reducing hull biofouling, which builds up over time and increases drag, leading to higher fuel consumption. Regular use of the system prevents further fouling and ensures long-term efficiency. While the study did not account for the cumulative benefits of repeated cleaning, it highlighted the economic advantages of proactive hull cleaning, with a return on investment (ROI) achieved in under three months for both vessels.

Dr. Uwe Hollenbach, Senior Principal Consultant at DNV Maritime Advisory, emphasized the role of hull cleaning in the decarbonization of shipping. “The findings of this case study emphasize the critical role of minimizing biofouling in reducing greenhouse gas emissions from shipping,” he said, referring to the positive impact of proactive hull cleaning as outlined in DNV’s Maritime Forecast to 2050 report.

This development aligns with Hapag-Lloyd’s broader sustainability goals, demonstrating how innovative technology can reduce both emissions and operational costs. “This is an excellent example of how Hapag-Lloyd promotes sustainable maritime transport, by implementing innovative technology leading to reduced emissions and improved financial performance both in the short and long term,” Bhatia concluded.

Hapag-Lloyd’s commitment to sustainability is also reflected in its investment in cutting-edge technologies such as ITCH, which not only contribute to a cleaner environment but also improve the company’s bottom line. The ITCH system, by keeping hulls clean and enhancing vessel performance, is a key tool in Hapag-Lloyd’s efforts to reduce its environmental footprint and support a healthier ocean and planet.

Table of Contents

About Hapag-Lloyd

Hapag-Lloyd is a global leader in container shipping, with a fleet of 292 modern container ships and a total transport capacity of 2.3 million TEU. The company operates in 139 countries with 399 offices and offers reliable connections between over 600 ports worldwide. Hapag-Lloyd is also involved in terminal operations, with equity stakes in 20 terminals across Europe, Latin America, the United States, India, and North Africa.

About Shipshave ITCH

The Shipshave ITCH system is a semi-autonomous robot that operates by gently brushing away fouling from a vessel’s hull during transit. The system is easy to deploy and requires no physical installation, making it a highly effective solution for maintaining hull performance and energy efficiency. By utilizing water flow across the hull, ITCH is able to clean and optimize vessel performance without disrupting operations, helping shipowners manage energy use and reduce environmental impact.

About Shipshave

Shipshave is a technology company specializing in proactive hull performance management solutions. Founded in 2019 and headquartered in Stavanger, Norway, Shipshave has developed innovative solutions like the ITCH system to optimize vessel performance, reduce costs, and improve sustainability in shipping. The company has installations across more than 30 shipowners and continues to lead the way in hull cleaning technology.

Source Shipshave